WHAT IS SMT ASSEMBLY?

In simple terms, a small machine that assembles electronic components is known as a small machine tool. The technology behind these machines has evolved significantly over the years, and today’s small machine tools can handle a wide range of tasks, from simple component placement to more complex assembly operations.

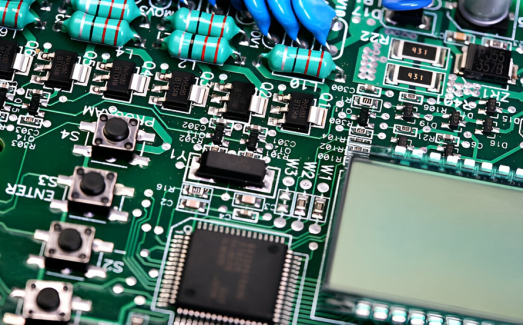

1.What Is SMT Assembly?

SMT assembly is a process of mounting surface-mount components onto a PCB. The process is also known as pick-and-place.

There are two main types of SMT assembly: through-hole and surface-mount. Through-hole components are inserted into holes drilled in the PCB and then soldered in place. Surface-mount components are placed directly onto the PCB surface and soldered.

SMT assembly is a more efficient process than through-hole assembly, as it requires fewer steps and less time. SMT components are also smaller and lighter than through-hole components, making them ideal for use in portable electronic devices.

The SMT assembly process can be divided into four main steps:

- Component preparation

- Component placement

- Soldering

- Inspection

- Component Preparation

The first step in any SMT assembly process is component preparation. This involves preparing the PCB surface for component placement and ensuring that all components are correctly orientated and positioned.

- Component Placement

The next step is to place the components onto the PCB. This can be done manually or using an automated pick-and-place machine.

- Soldering

Once all the components are in place, the PCB is ready to be soldered. This can be done using a reflow oven or a wave soldering machine.

- Inspection

After soldering, the PCB is inspected for defects. This is done using visual inspection, X-ray, or other methods.

SMT assembly is a vital part of the electronics manufacturing process. By understanding the basics of the process, you can ensure that your products are assembled correctly and efficiently.

2.How SMT Assembly Works

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of a printed circuit board (PCB).

An SMT assembly line generally consists of four main process steps:

- Component placement: The SMT components are placed on the PCB using a pick-and-place machine.

- Reflow soldering: The PCB and components are then passed through a reflow oven, where the solder paste is melted and the components are soldered to the PCB.

- Wave soldering (optional): In some cases, the PCB may then be passed through a wave soldering machine, where additional solder is applied to the through-hole components.

- Inspection and testing: The finished PCB is then inspected and tested to ensure that it meets the required specifications.

SMT assembly offers a number of advantages over through-hole assembly, including:

- Increased component density: SMT components are much smaller than through-hole components, so more components can be placed on a given PCB.

- Increased assembly speed: SMT components can be placed and soldered much faster than through-hole components.

- Reduced assembly costs: SMT assembly is generally less expensive than through-hole assembly.

- Reduced board size and weight: SMT components generally require less board space than through-hole components, and the resulting PCBs are typically lighter in weight.

- Improved reliability: SMT soldering is generally more reliable than through-hole soldering, due to the fact that the solder connection is made on both sides of the PCB.

- Increased design flexibility: SMT components can be placed on both sides of the PCB, allowing for more complex designs.

Despite these advantages, SMT assembly does have some disadvantages, including:

- Increased design complexity: The increased design complexity associated with SMT assembly can make it more difficult to troubleshoot and repair problems.

- Increased material costs: The smaller size of SMT components generally results in higher material costs.

- Reduced thermal

3.The Advantages of SMT Assembly

Surface-mount technology (SMT) is a method in which the components are mounted or placed directly onto the surface of a printed circuit board (PCB).

The main advantages of SMT assembly are:

- Reduced assembly time

- Reduced assembly cost

- Reduced board size and weight

- Increased reliability

- Increased component density

4.The Disadvantages of SMT Assembly

Surface-mount technology (SMT) assembly is a process of mounting electronic components onto the surface of a printed circuit board (PCB). This type of assembly is generally used for smaller electronic devices such as cell phones, computers, and portable music players. While SMT assembly offers a number of advantages, there are also some disadvantages to consider.

One of the biggest disadvantages of SMT assembly is the high initial investment cost. The equipment required for SMT assembly is much more expensive than the equipment required for through-hole assembly. This means that manufacturers must be willing to make a significant up-front investment in order to use SMT assembly.

Another disadvantage of SMT assembly is the potential for component damage. Because components are mounted on the surface of the PCB, they are more vulnerable to physical damage. This can be a problem during the shipping and handling of finished products.

Another potential issue with SMT assembly is the potential for solder joint problems. If the solder joints are not properly made, they can be susceptible to cracking and other issues. This can lead to reliability problems and may require expensive repairs.

Overall, SMT assembly offers a number of advantages and disadvantages. Manufacturers must carefully consider these factors when deciding whether or not to use SMT assembly for their products.

5.How to Choose the Right SMT Assembly for Your Project

When it comes to choosing the right SMT PCB Assembly for your project, there are a few things to keep in mind. First, you need to know what your project’s requirements are. Second, you need to know what options are available to you.

Third, you need to consider the cost of the assembly. Fourth, you need to decide if you want an in-house assembly or an outsourced one. Fifth, you need to consider the lead time for the assembly.

Here are a few things to keep in mind when choosing the right SMT assembly for your project:

- Know your project’s requirements:

The first step is to know what your project’s requirements are. What are the components that need to be assembled? What is the quantity that you need? What are the tolerances that need to be met?

- Know your options:

Once you know your project’s requirements, you need to know what options are available to you. There are a few different types of SMT assemblies, and each has its own set of benefits and drawbacks.

- Consider the cost:

The cost of the assembly is an important consideration. You need to balance the cost of the assembly with the quality of the assembly.

- Decide if you want an in-house assembly or an outsourced one:

Another important consideration is whether you want an in-house assembly or an outsourced one. There are benefits and drawbacks to both options.

- Consider the lead time:

The lead time for the assembly is another important consideration. You need to make sure that the assembly can be completed in a timely manner.